Gravitational equilibrium & the square cube law

‘Gulliver’s Travels’ is a classic of English Literature written by Jonathan Swift in 1726. It is intended to be a satire of human nature and ‘travellers’ tales’. In the book its protagonist visits the fictional countries of Lilliput and Brobdingnag. The citizens of the former are 12 times smaller than Gulliver and in the latter they are 12 times bigger.

Of course every reader of the book knows that Lilliput and Bribdingnag are fictional, but perhaps fewer might realise that they are necessarily fiction in any possible world that follows the same physical laws as our own. The reason for this is described by the square cube law, which was first attributed to Galileo.

According to this law the size of things cannot be indefinitely scaled up, because the physical properties of objects change as they increase in size. Consider a cube with sides one unit long. If we were to double the length of each side then the surface area of each face will increase from 1 to 4 units. The volume of the cube, and by extension the quantity of stuff from which it is made, increases from 1 to 8 units i.e. doubling the linear dimensions causes the surface area to be squared and the volume of stuff to be cubed.

In other words the rate at which the volume and weight of an object increase with size is greater than the rate at which its linear dimensions and surface area increase.

Conversely, the strength of things, normally expressed as a limiting stress, is independent of size [1]. It follows that as things become larger, while retaining their original proportions, they will eventually reach a point where they can no longer support their own weight. This places an upper limit on how big things, including people, can get.

This is a vexing problem for modern day architectural students, who are surprised to learn that the model they have spent hours building does not prove that the structural gymnastics their design requires are viable in the real world.

There is of course an exception to the square cube law, though not a true exception. The square cube law does not cease to work, rather it is not discernible within the normal range of scaling for certain objects.

An example of such an object from the natural world would be a mountain. An equivalent structure form the man-made world would be a pyramid. Both structures come from a class of things that share three key ingredients. Firstly, they are both made of stone, which is a natural material with a very high compressive strength and low tensile strength. Secondly, they are both compression structures that assiduously avoid tension. Thirdly, they are stocky and solid structures. Not solid in the sense that they are strong, though that is indeed true, but solid in the sense that they are not hollow. The implication of being stocky and solid is that they are not prone to buckle, as a slender or thin walled structure is. A second implication of stockiness is a large cross-section, which implies low stress.

These then are the ingredients for subverting Galileo’s square cube law and within the class of things which have these ingredients there is a group of structures that does so with a style and panache that is difficult to surpass. They laugh in the face of the square cube law.

I am of course talking about gothic structures; those great stone cathedrals of the late medieval period with their quadripartite vaults and flying buttresses. I am often asked, mainly by my dad, how it was that medieval masons created such structures in the absence of modern structural theory. The stock answer is that they used rules of thumb, but for me there has to be more to it than that.

How on earth did they manage to design structures, using rules of thumb, that modern analysis shows us to have near perfect proportions. Rules of thumb are intended to apply generally, but must necessarily be derived from the particular. The further a design departs from the particular the less useful a rule of thumb is.

Gothic structures do have similarities, but there is also great variety in their design, which ought to make rules of thumb less helpful.

Perhaps the answer to this dilemma is to be found in a process of trial and error. While there was undoubtedly a role for trial and error I am not convinced that it played a central role, at least not in the commonly understood sense. I hold this view for several reasons:

Firstly, most cathedrals took hundreds of years to build and though master masons may have worked on several, they would not, in their own lifespan, have time to learn all the necessary forms by trial and error. This brings us back to rules of thumb. Secondly, while there is evidence of design evolution over time there is relatively little evidence of major failures, which is odd given the innovative, and often spectacular, designs adopted. Furthermore, when known failures occurred they were often, though not always, associated with abnormal events like earthquakes or phenomena external to the structure like differential settlement.

We therefore have much evidence of trying daring new things, but scant recorded evidence of failure [2]. This is not entirely a surprise, because cathedrals are expensive and their proprietors were not stupid. Master masons would not have been in charge for long if their structures kept collapsing.

To find a satisfactory explanation I think we need to return to the square cube law. If a structure could be designed to subvert the square cube law then a successful pattern would be successful at any scale. It follows that if you could demonstrate a particular form of structure would stand using a small model made of wood then it would also stand if it was scaled up to full size.

I do not know whether masons understood that they were subverting the square cube law. I suspect that they didn’t, but I do think that they understood perfectly well the load-paths and principles that were necessary to keep a stone structure in equilibrium. I think they fully understood that tension was the enemy and that gravity must be harnessed to maintain compression in all parts of the structure.

They were specifically designing structures to achieve gravitational equilibrium and they were doing it by experimentation with scale models. They then used rules of thumb, derived from these models, to scale up their findings to full size structures.

Happily for the masons this methodology was just perfect for avoiding the square cube law, whether they knew it or not, and in this way spectacular and innovative designs could be realised without needing to know anything about materials science, stresses or strains.

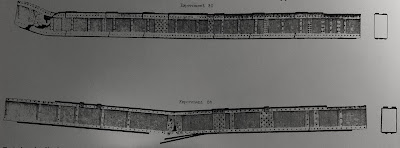

While this theory involves a heavy dose of speculation it is not without evidential support. For example, we know that Antonio Vicenzo the designer of San Petronio church in Bologna commissioned a model of brick and plaster at circa one eighth scale. It was around 19m long and 6m high. I expect that it was used to convey the design to its proprietors, but I don’t think it is too great a leap to posit that it might also have played a role in the church’s structural design.

[1] I accept that all bets are off at the atomic scale, but we don’t normally consider atomic forces when designing building structures, bridges and the like.

[2] I know that absence of evidence is not evidence of absence, nevertheless evidence is sometimes notable by its absence, particularly when there might be a reasonable expectation to find some.